Learn about the production of compartment boxes and their cartoning machines

Compartment boxes are an essential packaging solution for a variety of industries, including food, cosmetics, pharmaceuticals, and electronics. These boxes have internal partitions to separate items, ensuring protection and organized storage. The production of compartment boxes relies heavily on advanced **cartoning machines**, which simplify the production process while maintaining precision and efficiency.

What are compartment boxes?

Compartment boxes are a type of packaging designed with multiple compartments or dividers within a single container. These cartons are commonly used for:

Food packaging (e.g., chocolate boxes, pastry trays)

Cosmetics and fragrances (e.g., makeup palettes, gift sets)

Electronics (e.g., small device storage boxes)

Pharmaceuticals (e.g., pill boxes, medical kits)

The main advantage of compartment boxes is that they prevent products from moving, reduce damage during transportation, and enhance the appearance of products.

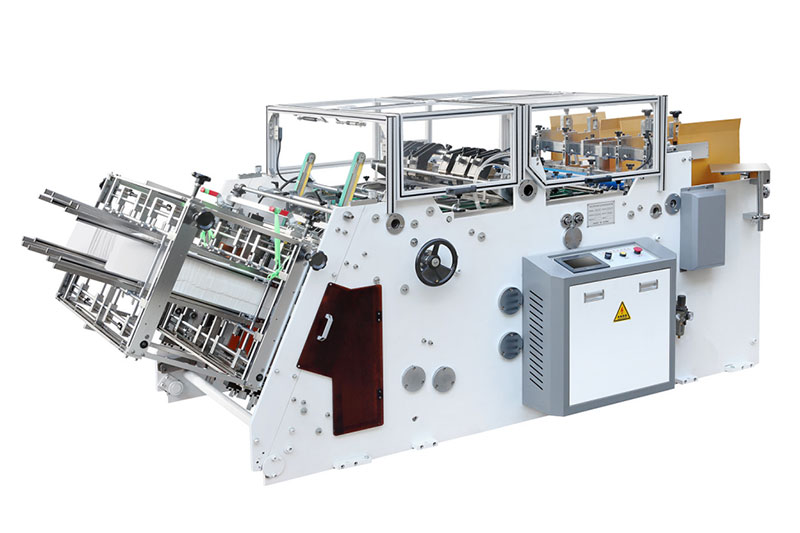

The role of cartoning machines in compartment box production

The manufacture of compartment boxes requires specialized cartoning machines that can perform precise cutting, folding, and compartmentalization. Here are the contributions of these machines:

1. Precision Cutting and Creasing

Modern carton machines use die-cutting technology to create precise compartment designs. Laser guidance systems ensure clean and aligned compartment edges.

2. Automatic Folding and Gluing

Automated machines fold and glue carton structures, ensuring consistency and reducing manual labor. This is critical for high-volume production.

3. Customizable Designs

With adjustable settings, carton machines can produce different compartment layouts, sizes, and shapes to meet specific industry needs.

4. Eco-friendly Production

Many machines now support recycled paper and biodegradable materials, making compartment cartons a sustainable packaging choice.

Choosing the Right Carton Making Machine

When choosing a carton making machine for producing interlayer boxes, consider the following factors:

Production speed (choose a high-speed machine for large-volume production)

Material compatibility (cardboard, corrugated paper, or eco-friendly materials)

Automation level (fully automatic or semi-automatic machine)

Customization capabilities (adjustable die-cutting dies for different designs)

Conclusion

Interlayer boxes provide efficient and organized packaging solutions for a wide range of industries, and advanced carton making machines make their production possible. These machines ensure precision, speed, and customization, making them an integral part of the modern packaging manufacturing industry.