The Benefits of Using a Box Forming Machine

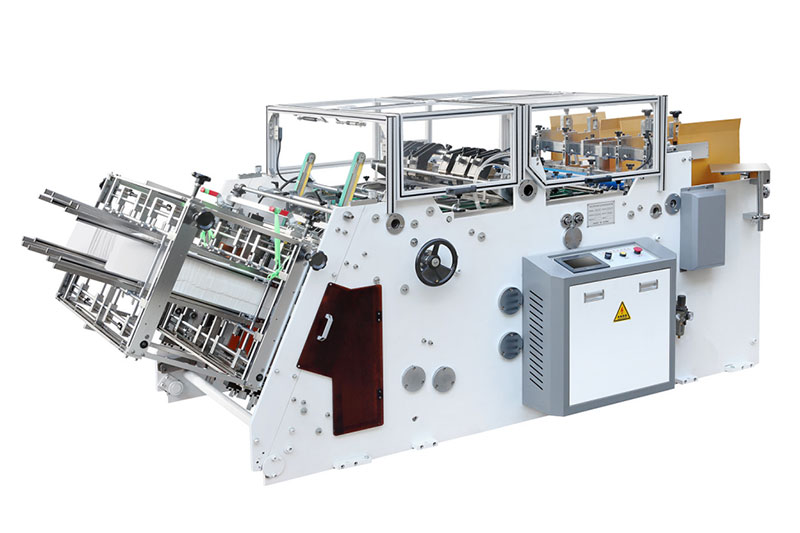

In today’s fast-paced manufacturing and packaging industries, efficiency, precision, and cost-effectiveness are crucial. One of the most effective ways to achieve these goals is by utilizing a box forming machine. These machines automate the carton production process, significantly enhancing productivity while maintaining high-quality standards. Below, we explore the key benefits of using a box forming machine and how it revolutionizes packaging operations.

The Benefits of Using a Box Forming Machine

Traditional manual carton assembly is time-consuming and labor-intensive. A high-speed paper carton erecting machine can form hundreds or even thousands of boxes per hour, far surpassing manual capabilities. Automation ensures consistent output, reducing bottlenecks in production lines and enabling businesses to meet high demand efficiently.

As stated:

The box forming machine can automate the carton production process, greatly improving production efficiency. It reduces the need for manual labor and accurately controls the size, shape, and quality of each carton. Compared with manual production, it is faster and more stable.

I.Reduced Labor Costs and Human Error

Manual box assembly requires significant workforce involvement, increasing operational costs. An automatic paper carton erecting forming machine minimizes dependency on manual labor, cutting down on wages and training expenses. Additionally, automation eliminates human errors such as inconsistent folding, misaligned seams, or incorrect box dimensions, ensuring uniformity in every carton produced.

II.Enhanced Precision and Consistency

Box forming machines are designed to produce cartons with exact specifications every time. Whether for e-commerce, food packaging, or industrial use, these machines maintain tight tolerances in size and shape. This precision is especially critical for industries requiring standardized packaging for automated filling and sealing processes.

III.Versatility in Box Design and Customization

Modern box forming machines can handle various box styles, including auto-bottom cartons, trays, and specialty packaging. Advanced models allow quick adjustments for different sizes and designs, making them ideal for businesses with diverse packaging needs. This flexibility supports customization without sacrificing speed or quality.

IV.Improved Workplace Safety

Manual box folding can lead to repetitive strain injuries or accidents due to improper handling of materials. Automated machines reduce physical strain on workers, creating a safer and more ergonomic work environment.

V.Cost-Effective and Sustainable Packaging Solutions

By optimizing material usage and reducing waste, box forming machines contribute to sustainable packaging practices. They ensure precise cuts and folds, minimizing excess cardboard waste. Additionally, faster production means lower energy consumption per unit, enhancing overall cost efficiency.

Conclusion

Investing in a high-speed paper carton erecting machine or an automatic paper carton erecting forming machine offers numerous advantages, from boosting productivity to ensuring consistent quality. Businesses looking to streamline packaging operations, reduce costs, and enhance efficiency should consider integrating these advanced machines into their production lines.

By leveraging automation, companies can stay competitive in an increasingly demanding market while maintaining high standards in packaging performance.