The Different Types of Die Cutting: A Comprehensive Guide

Die cutting is a versatile manufacturing process used to cut, shape, and form materials into precise designs. It is widely used in industries such as packaging, automotive, textiles, and electronics. Among the various die-cutting methods,roll die cutting is particularly popular for high-volume production. In this article, we’ll explore the different types of die cutting, with a special focus on roll die cutting and its applications.

What are the different types of die cutting?

Die cutting includes several types, such as flatbed (using hydraulic presses for thick materials like foam), rotary (high-speed cutting for films or adhesives), laser (precision digital cutting for fabrics), waterjet (for heavy materials like metal), and digital (CNC-based for prototypes), each suited for different materials and production needs.

1. Flatbed Die Cutting

Flatbed die cutting is one of the most traditional methods, where a flat die presses against the material to cut it into the desired shape. This method is ideal for:

Thick or rigid materials (e.g., foam, rubber, metal)

Low to medium production volumes

Precision cutting with minimal waste

2. Rotary Die Cutting

Rotary die cutting uses cylindrical dies that rotate to cut materials as they pass through the machine. This method is highly efficient for:

High-speed production

Continuous materials (e.g., labels, adhesive tapes)

Thin to medium-thickness materials

3. Laser Die Cutting

Laser die cutting employs a high-powered laser to cut materials with extreme precision. It is best suited for:

Intricate designs and fine details

Prototyping and custom jobs

Materials that cannot withstand mechanical pressure

4. Digital Die Cutting

Digital die cutting uses computer-controlled blades or lasers to cut designs without physical dies. This method is great for:

Short runs and custom projects

Quick design changes

Paper, vinyl, and lightweight fabrics

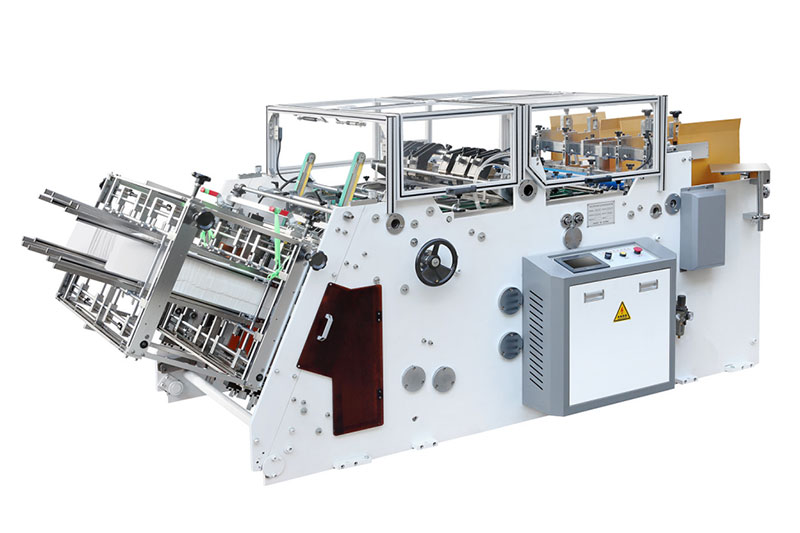

5. Roll Die Cutting

Roll die cutting is a specialized form of rotary die cutting, where the material is fed through rollers containing the die. This method is highly efficient for:

Mass production of consistent shapes

Flexible materials (e.g., films, foils, thin plastics)

Applications requiring high precision and speed

Advantages of Roll Die Cutting:

High-speed processing – Ideal for large-scale manufacturing

Reduced material waste – Optimizes material usage

Consistent quality – Ensures uniformity in every cut

Versatility – Works with adhesives, films, and thin substrates

Common Applications of Roll Die Cutting:

Label and sticker production

Medical device components

Packaging materials

Electronic insulation films

Conclusion

Die cutting is a crucial process in modern manufacturing, with each method offering unique benefits. Roll die cutting, in particular, stands out for its efficiency and precision in high-volume production. Whether you need intricate laser cuts, flexible digital solutions, or rapid rotary processing, choosing the right die-cutting method depends on your material, design complexity, and production requirements.

Would you like to learn more about how roll die cutting can optimize your production process? Contact a die-cutting specialist today!

This article provides a clear overview of die-cutting methods while emphasizing roll die cutting as a key technique. Let me know if you'd like any modifications or additional details!